Vinamilk owns more than 200 product lines sold at 251,000 retail points, 430 stores nationwide, and exported to 57 international markets. With such a large scale, what keeps the brand running smoothly? Let’s explore Vinamilk’s supply chain model in the following article by Kamereo!

Vinamilk’s Supply Chain Model

Vinamilk is the leading dairy producer in Vietnam, with a diverse product portfolio. Their main products include liquid milk and powdered milk. Value-added products like condensed milk, yogurt, drinking yogurt, ice cream, and cheese are also popular in the market.

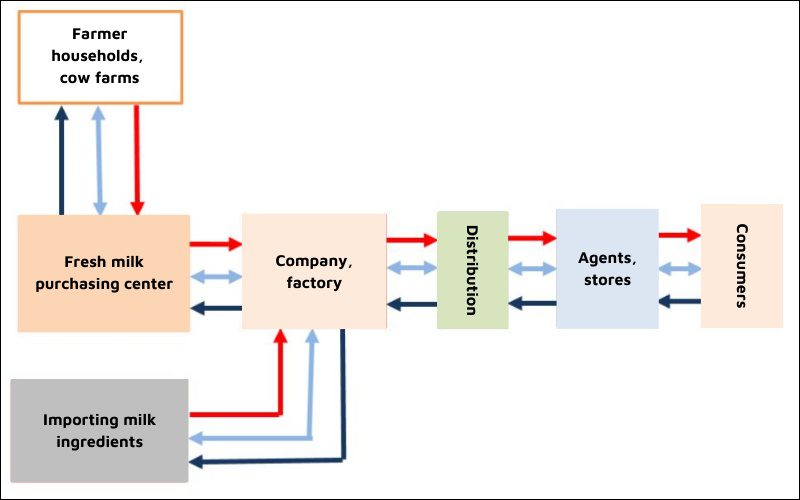

Vinamilk’s supply chain model is managed through three main streams: product flow, information flow, and financial flow. You can refer to the diagram below for an overview of this brand’s supply chain model.

Notes:

- The red arrow represents the movement of the product flow.

- The light blue arrow represents the exchange of information flow.

- The dark blue arrow represents the inflow and outflow of financial flow.

Components Involved in the Supply Chain

To understand Vinamilk’s supply chain model, let’s delve into the details of each component below:

Vinamilk Suppliers

Vinamilk’s input materials come from two main sources: imported materials and materials purchased from domestic farmers and farms.

Imported Materials

Vinamilk prioritizes sourcing materials from countries with advanced agriculture to ensure safety and quality standards. These sources include the USA, New Zealand, and Europe.

Some notable suppliers are:

- Fonterra (SEA) Pte Ltd: Raw milk powder

- Hoogwegt International BV: Raw milk powder

- Perstima Binh Duong: Steel cans

- Tetra Pak Indochina: Paper packaging

Domestic Materials

Vinamilk establishes centers to collect fresh milk from farmers and farms. They also measure the milk’s weight, check its quality, store it, and transport it to the production plants. These centers provide farmers with information on quality, prices, material demand, and make payments to dairy farmers.

Finished Product Production

Vinamilk applies modern production and packaging technology from Germany, Italy, and Switzerland in all its factories. Additionally, the company owns machinery using Niro’s spray-drying technology (Denmark), the only one in Vietnam. Vinamilk also uses internationally standardized production lines from Tetra Pak for producing milk and related products.

Vinamilk has large-scale production facilities in New Zealand, the USA, and Poland. In Vietnam, the company has 13 modern dairy factories from North to South. Notably, the mega dairy factory in Binh Duong at My Phuoc 2 Industrial Park spans 20 hectares.

Vinamilk also has ISO 17025-certified laboratories in chemistry and biology. All Vinamilk’s production plants have environmental management systems meeting ISO 14001:2004 standards.

Product Distribution – Output

Finally, the distribution of finished products is crucial in Vinamilk’s supply chain. The company has a system for both domestic and international markets.

Vietnam Market

Vinamilk has a strong and extensive distribution network nationwide, ensuring consumers access products conveniently, quickly, and in optimal conditions. Vinamilk’s distribution system includes:

- Distribution partners (General Trade – GT channel)

- Supermarket chains nationwide (Modern Trade – MT channel)

- Vinamilk product introduction and sales stores nationwide

- Direct distribution to customers like enterprises, schools, and amusement parks (KA channel)

International Market

According to statistics, Vinamilk products are available in over 40 countries and territories worldwide, including Cambodia, Thailand, South Korea, Japan, Taiwan, Turkey, Russia, Canada, the USA, and Australia. Key export products include children’s milk powder, nutritional powder, condensed milk, liquid milk, beverages, soy milk, and yogurt.

Factors Creating Value Chain in Vinamilk’s Supply Chain

Vinamilk’s supply chain is a case study worth learning from. Here are five factors that give the company a competitive advantage over its rivals:

Self-sufficiency in Input Materials

Vinamilk’s crucial goal is investing in dairy farms to ensure self-sufficiency in fresh milk supplies. This long-term strategy helps improve quality and increase localization of material sources. Currently, the total number of cows providing milk for Vinamilk from farms and contracts with farmers is over 160,000, supplying more than 1,000 tons of raw fresh milk daily for producing fresh milk products.

In 2001, Vinamilk had 70 fresh milk transit agents; now, there are over 600 nationwide, collecting over 230 tons of milk per day. All agents are well-organized and distributed reasonably, allowing farmers to deliver milk conveniently and quickly.

Vinamilk’s Milk Collection Process

Milk collected from farms must always meet the quality standards agreed upon between Vinamilk and domestic dairy farms. Therefore, milk collection centers play a crucial role in gathering milk from farmers and farms through collection stations.

Activities at the centers include measuring milk weight, checking quality, and storing the product before transporting it to production plants. Additionally, the centers provide farmers with information on quality, prices, and material demand. They also handle payments to dairy farmers after purchasing milk.

Application of Technology in the Supply Chain Process

The LGV (Laser Guided Vehicles) robots automatically transport pallets of products to the warehouse area in Vinamilk’s dairy factories. LGV also handles the automatic transportation of packaging rolls and materials to the machinery. Additionally, this robotic system is designed to self-charge its batteries without human intervention.

Vinamilk’s dairy factories are equipped with sterilized fresh milk production lines using modern technology and advanced equipment. Moreover, all factory operations are fully automated and closed from the input of raw materials to the final product.

Specifically, the factory features a smart warehouse system covering 6,000 m² with 20 loading and unloading docks. Goods are automatically handled by RGVs (Rail Guided Vehicles) for transporting product pallets into the warehouse and stacker cranes for arranging pallets onto the racking system. Additionally, the management of inbound and outbound goods is based on SSI Schaefer’s Wamas software, ensuring order optimization, and efficient management of goods movements and resources.

The Wamas warehouse management system integrates with the ERP management system and Tetra Plant Master automation solution. This ensures seamless connectivity in factory operations from production planning, raw material intake, to final product dispatch.

Optimization of Equipment Operation Time

A notable aspect of Vinamilk’s supply chain is the continuous improvement of energy efficiency at production farms. All machinery and equipment operations are regularly reviewed for reallocation and optimization of operation time.

Specifically, the operation times of equipment clusters throughout the day are adjusted to align with production schedules. This helps minimize electricity use during peak hours to save costs. Vinamilk also places high importance on water recycling and reuse in sustainable management.

GEA’s water flushing method is used for manure collection, which is not only effective in waste treatment but also in recycling wastewater. This positively contributes to the environment and optimizes water use. This technology is currently applied at the TNTH Dairy Farm and is under consideration for future investment.

Vinamilk also performs periodic maintenance for mechanical equipment on a scheduled basis with standardized content to optimize operation and increase energy efficiency. Performance evaluation and fuel management are conducted for each type of motorized vehicle and fuel-using equipment to ensure no wastage occurs during operation.

Priority on Recycling and Reuse

Vinamilk has invested in and tested a hot water production system using Biogas at the Tay Ninh Farm with highly effective results. This reduces environmental pollution, energy costs, and enhances efficiency. Therefore, the system is widely applied across Vinamilk’s farms, benefiting milk pasteurization, pail washing, and providing water for calves.

To reduce packaging costs and ensure quality calf feed, Vinamilk has invested in automated silo feed systems across all farms. This not only optimizes costs and ensures calf nutrition but also significantly reduces labor and equipment costs. Additionally, the system reduces packaging use, contributing to environmental protection.

Five Lessons from Vinamilk’s Value Chain

The success of Vinamilk’s supply chain offers valuable lessons for organizations to study and apply. Here are some key takeaways:

Increasing Awareness of Supply Chain Importance:

Managers need to recognize that supply chain management is not just a specialized function but a strategic component of the business. Vinamilk’s leadership has invested in building a scientifically sequenced and streamlined supply chain, enhancing order processing speed, packaging, and delivery to consumers.

Perfecting an Integrated Information System

Vinamilk’s information standards are quick, clear, and easy to understand, meeting the demands of each supply chain stage. Therefore, applying precise information storage, transmission, and processing technology enhances the overall supply chain efficiency.

Strengthening Partnerships

A crucial lesson from Vinamilk’s supply chain is maintaining strong relationships with input and output partners. Vinamilk prioritizes reputable collaboration to effectively connect manufacturers and retailers. The company’s supplier and distributor selection processes are stringent, with clear contracts outlining both parties’ rights and responsibilities.

Minimizing Risks from Imported Sources

Vinamilk constantly seeks alternative supply options and aims for raw material self-sufficiency. While importing materials saves production costs, it also introduces risks. For example, import-export activities nearly halted during the peak of the COVID-19 pandemic (2019-2020). Therefore, Vinamilk focuses on self-sufficiency policies, risk prevention measures, and rapid business recovery when threats arise.

Building a Socially Responsible Brand Image

Vinamilk emphasizes community support activities and children’s health care, building a positive brand image. Through these activities, the company’s core message and values are widely propagated, significantly improving business performance.

Conclusion

The above information outlines Vinamilk’s supply chain. The company has successfully managed operations from raw material intake to final product output. Additionally, Vinamilk has established a positive brand image through its value chain activities. Follow the F&B Business Experience section for more useful information!

Read more: