Optimizing Coca Cola’s supply chain requires finding local partners to ensure Coca-Cola production time and materials. However, meeting the requirements of Coca-Cola Vietnam is not an easy task. Join Kamereo to learn in detail about the supply chain and distribution channels of Coca Cola – the world’s largest soft drink brand in the following article!

Table of Contents:

Table of Contents

- Coca Cola Supply Chain Diagram

- Supplier

- Coca Cola Production Operations

- Product Transportation

- Coca Cola Distributors

- Retailers

- Consumers

- Reverse Logistics

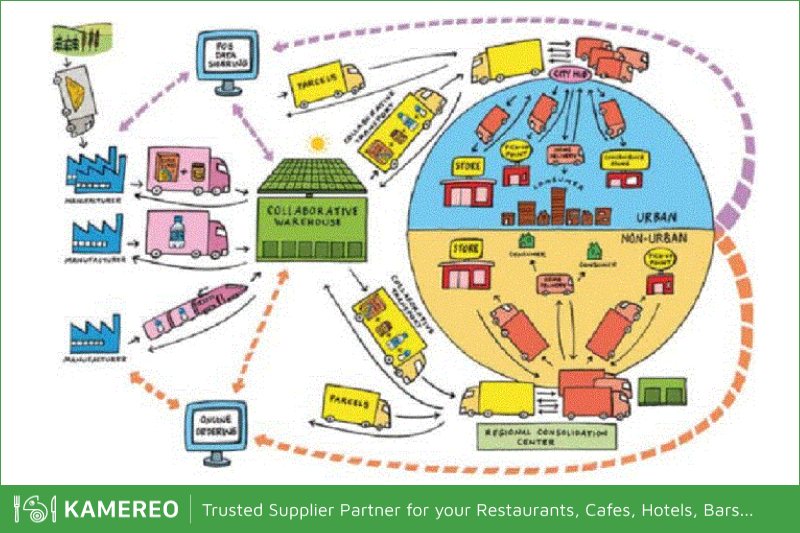

Coca Cola Supply Chain Diagram

According to Coca Cola’s annual report, the company currently has 225 bottling partners globally. These partners are responsible for the production process, creating products based on the concentrated samples sent from the company’s factory. After the production process, the products are packaged on-site and transported to distribution points locally or in neighboring regions.

Additionally, Coca Cola employs the SCOR model, a global supply chain management tool, to enhance the efficiency and performance of its supply chain. Developed by the Supply Chain Council in 1996, this model has been applied by Coca Cola since 1998.

Supplier

The first link in Coca Cola’s supply chain is the supplier. This is a crucial factor in determining product quality. Coca Cola has two main supplier groups: raw material suppliers and packaging suppliers.

Raw Materials

Raw materials play a vital role in ensuring product quality. For each beverage ingredient, Coca Cola Vietnam seeks reputable partners based on criteria such as:

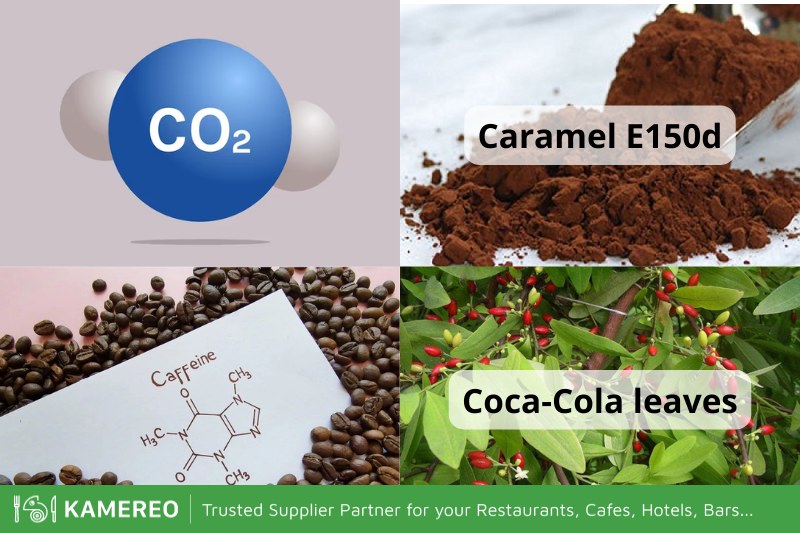

- CO2 (Carbon Dioxide): Used to create acidity, aid digestion, and prevent microbial growth.

- Food color (Caramel E150d): Produced from melted sugar or ammonia chemical.

- Acidulants (Phosphoric Acid – E330): Used to create acidity and act as a preservative, constituting 50% of the acid in the formula.

- Caffeine: Extracted from natural sources like coffee, tea leaves, cola nuts, or synthetic caffeine.

- Sugar: Supplied by the KCP Sugar Factory.

- Natural flavors: Formula is kept secret and provided by The Coca Cola Company.

- Water: Supplied from the plant in the region.

- Coca leaves: Supplied by the processing company Stepan, located in Illinois, USA.

To ensure competitiveness, Coca Cola does not publicly disclose the supply sources for some ingredients.

Product Packaging

Coca Cola’s product packaging is sourced from suppliers such as:

- Bottle packaging: Supplied by the limited liability company Dynaplast Packaging (Vietnam).

- Carton packaging: Supplied by Bien Hoa Packaging Joint Stock Company.

- Coca Cola packaging is provided by two separate suppliers.

Coca Cola Production Operations

Production organization is central to Coca Cola Vietnam’s supply chain. This operation is divided into two main parts:

- The Coca Cola Company (TCC): This department is responsible for manufacturing and providing Coca Cola concentrate to bottling plants. Additionally, TCC handles brand marketing and management concerning Price, Product, and Promotion – three critical factors in marketing strategy.

- The Coca Cola Bottler (TCB): This department is responsible for production, warehouse management, distribution, and service provision for Coca Cola products. TCB is also in charge of the Place – the fourth factor in marketing strategy.

In 2017, Coca Cola Journey announced that Coca Cola Vietnam employs around 2,500 employees, with over 99% being Vietnamese. The company manages three large factories in Hanoi, Da Nang, and Ho Chi Minh City. With 100% foreign investment, these factories play a crucial role in the supply chain, ensuring product supply for the Vietnamese market.

Product Transportation

The product transportation process in Coca Cola’s supply chain is continuously adjusted in real-time through advanced operating technology. Company delivery trucks are equipped with GPS tracking devices to ensure that products reach distribution points within 48 hours of production.

This tracking process is performed daily with clear statistical reporting. Coca Cola constantly optimizes cargo transportation operations, minimizing the time for products to reach customers. To address the challenges of managing a large number of vehicles with varying delivery requirements, Coca Cola has implemented route optimization technology. This involves dividing delivery orders into appropriate time slots to minimize the impact of peak hours. This process not only helps reduce fuel costs but also ensures customer and partner satisfaction.

Coca Cola Distributors

Due to the fast-moving consumer goods (FMCG) industry’s nature, Coca Cola’s distribution in the supply chain is carried out by a large-scale network of wholesale distributors to meet substantial inventory volumes.

Products are transferred from manufacturers to wholesale distributors, who then distribute them to retail stores for sale to consumers. This model helps Coca Cola expand its distribution reach and ensures its products are available in many locations, optimizing consumer access.

If customers need wholesale purchases for business activities, contact Kamereo for assistance. We are one of the authorized distributors of Coca Cola products in the Southern region. Striving for retail optimization, Kamereo continuously upgrades its website and app systems to provide the best experience for customers when choosing products.

Retailers

Coca Cola’s supply chain connects products with various retail channels, including restaurants, shopping centers, retail stores, etc. These channels serve as direct points of contact with consumers, performing basic distribution functions and adhering to available regulations.

With a strategy of delivering directly to sales points within 48 hours, as mentioned earlier, Coca Cola products are always ready on shelves and are continuously transported. This helps the company minimize intermediary costs, ensuring the quality and readiness of goods.

Consumers

Coca Cola’s products are designed to serve all customer groups, including children, teenagers, office workers, and households. This is a crucial step determining the success or failure of the business. Consumers directly consume the products, creating the target market and influencing other members in the supply chain, such as wholesalers, retailers, etc.

Moreover, consumers play an important role in directly influencing the sales of other members and the manufacturer. Any changes in consumer shopping behavior and demand can pose challenges to the business if not managed tightly.

Reverse Logistics

Coca Cola’s recovery process includes the recovery of product packaging and the main product.

Reverse Logistics for Product Packaging

To recover product packaging, Coca Cola has implemented the “Green Supply Chain” strategy. In practice, to produce a new Coca Cola bottle, 6% of new materials and 94% of recycled materials are needed, with 30% of the materials obtained from recycled bottles.

All distributors, retailers, and consumers participate in the bottle and product structure recovery process. Additionally, Coca Cola has opened a recycling plant for used bottle shells to address household waste and environmental issues.

Reverse Logistics for Products

This process helps the company quickly identify errors and weaknesses in the product to take appropriate corrective measures. Strong coordination with Coca Cola’s supply chain members enables flexible responses to consumer actions, reducing production costs and maintaining brand reputation.

In the past, Coca Cola Vietnam has faced product scandals and had to recall all faulty products. This requires cooperation from consumers through feedback and product discontinuation.

👉 Read more:

- Explore the fruit seasons of Vietnam with Kamereo!

- 3 Tips of Kamereo to Control Product Quality

- Boost Your F&B Store Sales with the 7 Best Online Food Delivery Services in Ho Chi Minh City

These are the details of Coca Cola’s supply chain model. If you want to start a business, especially in the fast-moving consumer goods (FMCG) industry, choosing the right supply chain model is crucial. Don’t forget that Kamereo is currently distributing many high-quality genuine products with intelligent logistics processes. Contact us at the hotline 0812 46 37 27 for advice!